Honor Cycles’ co-founder and all round bike whiz, Simon Laumet, knows a thing or two when it comes to tyres. He talks us through what to look out for when choosing a tyre and the signs of wear and tear you don’t want to miss.

First things first, check that the rubber is still tacky by looking for small cracks in the rubber around the tread and sidewalls: they will be fairly uniformly distributed as all of the rubber perishes at the same time. Cracks are a sign that the rubber has started to become stiff and brittle – bad news! This is less noticeable in the dry but can be very dangerous in the wet.

A perished tyre is also more prone to punctures as the rubber is less able to deflect small sharp items like glass or flint. Bits of grit can get lodged in the cracks, slowly wearing a hole into the tyre’s casing.

Now, look for ‘bald patches’ on the tyre surface, where the tread pattern (if one exists) is almost invisible. Also look at the cross-sectional curvature of the tyre to see if it has developed a flat section along the top of the tyre.

If you spot areas where the rubber is so thin that the underlying casing is showing through then don’t ride the bike. You’ll have no grip and wiping out in a corner is no fun, so don’t risk it.

Finally, while the tyre is fully inflated look for small random bulges that appear near cuts. This is a sure sign that the casing has been breached and is not holding its shape anymore. Look a little closer and you’ll usually be able to make out the inner tube trying to squeeze its way out from that breach.

If your wheels are off your bike and already deflated (just had a puncture perhaps?), take the tyre completely off the rim and visually inspect the inside of it. If you can see a cut, it means that the strength of the casing has been compromised.

Damaged casing is not safe to ride. The casing is the only thing that provides the tyre with the strength to hold air pressure. Even if you’ve only just purchased the tyre and the rubber is still good as new, it’s not worth the risk. Riding a torn or cut casing is like playing grenade ping pong – it’s only a matter of time before it blows, even if you left the safety pin in.

If any of these occur, congratulations – you’re due for a new tyre! There are some instances of casing damage where you can repair the tyre with something like a “tyre boot” but they can be a bit hit and miss. To get back to full performance and safety the only option is to replace the tyre. This can seem wasteful, and it is, so it’s important to properly recycle used tyres. The Earth will thank you!

If you haven’t tired of tyres just yet, read on…

Tyres are, obviously, a crucial part of any bike, but many people ride tyres well past their best. Being able to corner, slow down and accelerate ultimately depends on how much grip your tyre has with the ground. Assuming the tyre is correctly inflated to the recommended pressure, the level of grip a tyre can offer depends on three key factors; rubber tack, surface shape & texture, and casing integrity.

Rubber tack, or stickiness, is all down to the material properties of the rubber. Manufacturers will try to balance good cornering grip with low rolling resistance by creating special rubber compounds. The more exotic the compound, the more expensive the tyre. A good example is Continental’s “Black Chili” compound found on their high-end racing tyres. It is also quite common to see tyres with two or three different rubber compounds being used at the same time to maximise performance. They usually achieve this by having a harder low grip & low rolling resistance central band, with high grip super tacky rubber on the sides for cornering. All in all, the quality of your tyre’s rubber is what sets its maximum performance limit.

If rubber tack is what sets the tyre’s performance bar, then surface shape & texture is what allows the tyre to reach that bar. No matter how expensive the rubber compound is, if it’s damaged or not suitable for the terrain then you won’t make the most of it. This is why manufacturers will typically only have a few types of rubber compounds at their disposal yet be able to make many different types of tyres by simply changing the tread pattern or having different combinations of rubber compounds. A cyclocross tyre made from the same rubber as a road tyre will have far too much rolling resistance on tarmac, just like how a road tyre on mud will have no grip.

The same rule applies to a tyre that is wearing down; as the shape and texture change so does its performance characteristics, even if the rubber is still good.

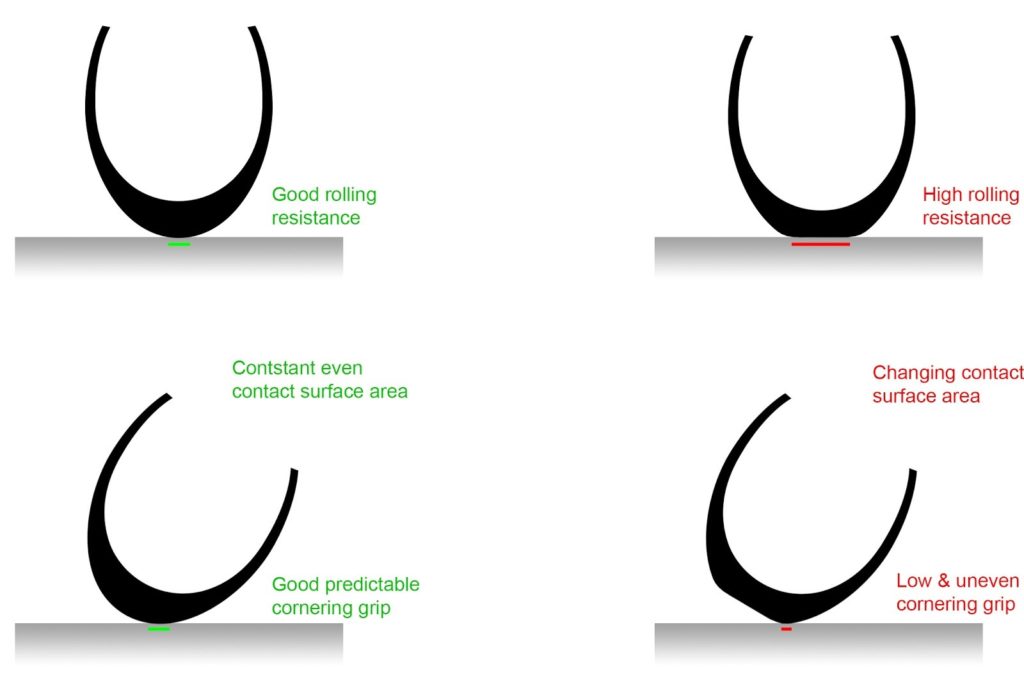

For example, when the curve of a road bike tyre wears down it begins to give more rolling resistance in straight lines and loses grip when cornering. This is all due to the development of a “flat” band along the middle of the tyre which increases surface area contact while riding in a straight line, and decreases surface area when cornering.

The casing is the structural base to which the tacky rubber is applied and moulded. Without casing the tyre would just be an expensive floppy rubber band. This base layer plays as important a role in performance as the other two factors, not only because it is the literal foundation of the tyre, but because its construction dictates how the tyre deforms and rolls.

You may have heard about TPI in marketing about some new tyres, and although it can be used as a good Tyre Price Index, it actually refers to the casing’s construction. TPI is the number of threads there are in a given inch of tyre casing. The more threads, the more flexible and compliant the tyre will be, making it more responsive to bumps and changes in the ground surface. You can see this as being a tyre’s “resolution” for compliance, and just like TV, HD is a good thing. A high TPI number will have a positive impact on weight, comfort, grip, and rolling resistance. Awesome! Sadly that’s where the TV analogy ends. To fit more threads in a given inch you have to make the threads thinner which makes them weaker. A high TPI tyre’s casing will be more prone to damage which is why they tend to only be used on racing tyres while city tyres use a lower TPI count casing but with thicker heavy-duty threads.

If you need a hand changing your tyres or any other maintenance, Honor Cycles offer a whole range of servicing and repairs in London, perfect for busy cyclists in the city. Find out more about their monthly care plans and speedy services.